Erie Bronze & Aluminum is a leading bronze and aluminum sand casting manufacturer in Erie, Pa, and a sand casting supplier of non-leaded bronze sand castings. We pride ourselves on our ability to create high-quality bronze sand castings, quickly, efficiently, and accurately.

As a world-class bronze alloy and aluminum sand casting manufacturer, you can expect Erie Bronze to:

- Provide exceptional casting quality

- Provide a fast turnaround on quotes and orders

- Be flexible and easy to work with

Our focus on technology and quality control ensures we produce high-quality bronze sand castings according to customer specifications. At Erie Bronze & Aluminum, we specialize in non-leaded bronze sand castings that are used in various industrial applications around the world.

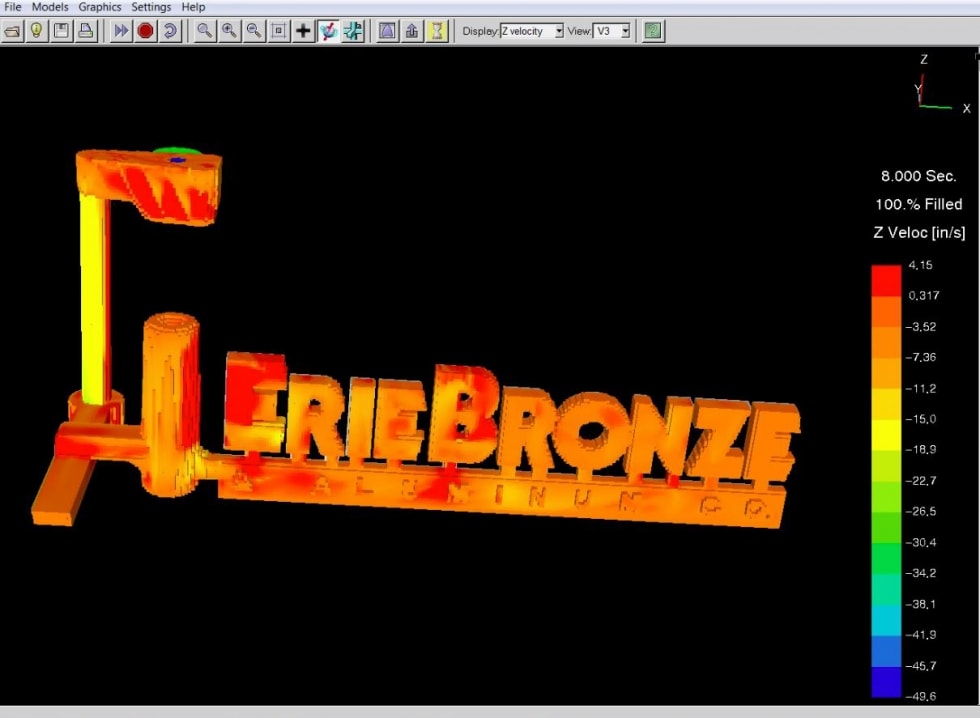

Simulation Software Assists in Manufacturing Quality Bronze & Aluminum Sand Castings

Erie Bronze & Aluminum’s engineering department uses SOLIDCast and FLOWCast software for design and flow simulations to help create castings and gating systems that reduce costs, shorten lead times, and produce higher quality castings. Flow simulation allows Erie Bronze & Aluminum to see a simulation of the liquid metal and the transferring of heat that occurs during the production of a specific casting before building a physical pattern or mold. Our engineers input a CAD model, and the software simulates to evaluate any complications, casting defects, or issues with the design.

Flow simulations allow Erie Bronze & Aluminum to reduce time spent on the sampling and first article inspection process, reduce the weight of material required for each mold, and ultimately lead to the production of high-quality bronze castings. Not only does SOLIDCast enhance our efficiency, but it reduces wasted time and material, which saves our customers money.

Bronze Sand Casting Capabilities, Alloys & Specifications

Aluminum Bronze | Manganese Bronze | Tin Bronze | Silicon Bronze

Erie Bronze & Aluminum casts various non-leaded bronze alloys for many different industries. All metals are alloyed in-house, using our SPECTROLAB metal analyzer.

Our foundry specializes in the following bronze alloys:

- Aluminum Bronze

- Aluminum bronze alloys are wear-resistant, non-sparking, and designed to withstand corrosion. These properties make aluminum bronze alloys suitable for applications exposed to seawater, chlorides, dilute acids, and other harsh environments.

- Manganese Bronze

- The strongest of the bronze alloys are manganese bronze alloys. They are mainly utilized for heavy-duty mechanical products due to their ability to operate under hefty loads and speeds, as well as their high tensile and yield strength.

- Tin Bronze

- Tin bronze alloys have reasonably high strength and excellent wear resistance, which makes them an excellent choice for bearings, piston rings, and gears. Like aluminum bronze alloys, tin bronze alloys are known for their corrosion resistance in marine applications.

- Silicon Bronze

- Silicon bronze alloys exhibit immense corrosion resistance when submerged in liquids or chemicals. Applications for silicon bronze alloys range from bearings and gears to intricately shaped pump and valve components.

Erie Bronze & Aluminum has experience working with several different bronze casting material specifications, including military, ASTM, and various aerospace applications.

A few of the most common sand bronze casting specifications we work with include:

- ASTM B148 – This Specification Establishes Requirements for Sand Castings Produced from Copper-Base Alloys

- AMS 4860 – Manganese Bronze, Sand, and Centrifugal Castings

- ASTM B584 – Standard Specification for Copper Alloy Sand Castings for General Applications

- ASTM B763 – Standard Specification for Copper Alloy Sand Castings for Valve Applications

- MIL-B- 21230A – Military Specification, Bronze, Nickel Aluminum, and Manganese-Nickel Aluminum Castings, Ship Propeller Application

- QQ-C- 390 – Military Specification Copper Alloy Castings

Erie Bronze & Aluminum is a Leading Bronze & Aluminum Sand Casting Manufacturer

Erie Bronze & Aluminum is more than just a bronze casting foundry. Our use of technology, including solidification software, allows us to efficiently produce and deliver quality castings that are customized to meet all of your requirements. Our state-of-the-art facility utilizes an automated sand casting process to provide quality products consistently. With decades of experience in the foundry industry, our team has the knowledge necessary to help you choose the best alloy for your application. In addition to bronze sand castings, we are also experts in manufacturing Aluminum Tubes & Rings in three hard-to-find alloys. Erie Bronze & Aluminum promises that our experienced and knowledgeable staff will take the time to understand your requirements and provide you with the highest level of customer service.