Our Services

Erie Bronze & Aluminum

Services Overview

Located in Erie, Pennsylvania, Erie Bronze & Aluminum specializes in non-ferrous bronze sand castings. Experienced in melting and pouring casting designs, we manufacture a number of bronze non-leaded alloys, including: aluminum bronze, manganese bronze, tin bronze, and silicon bronze. The state-of-the-art U.S. bronze foundry utilizes an automated sand casting process to produce repeatable high-quality products for a variety of industries. Erie Bronze & Aluminum manufactures bronze alloy castings which are used in a variety of applications, including glass container manufacturing and pressure-tight valves. Additionally, Erie Bronze & Aluminum specializes in manufacturing aluminum tubes and rings used in labyrinth seals, bearings, and bearing housings.

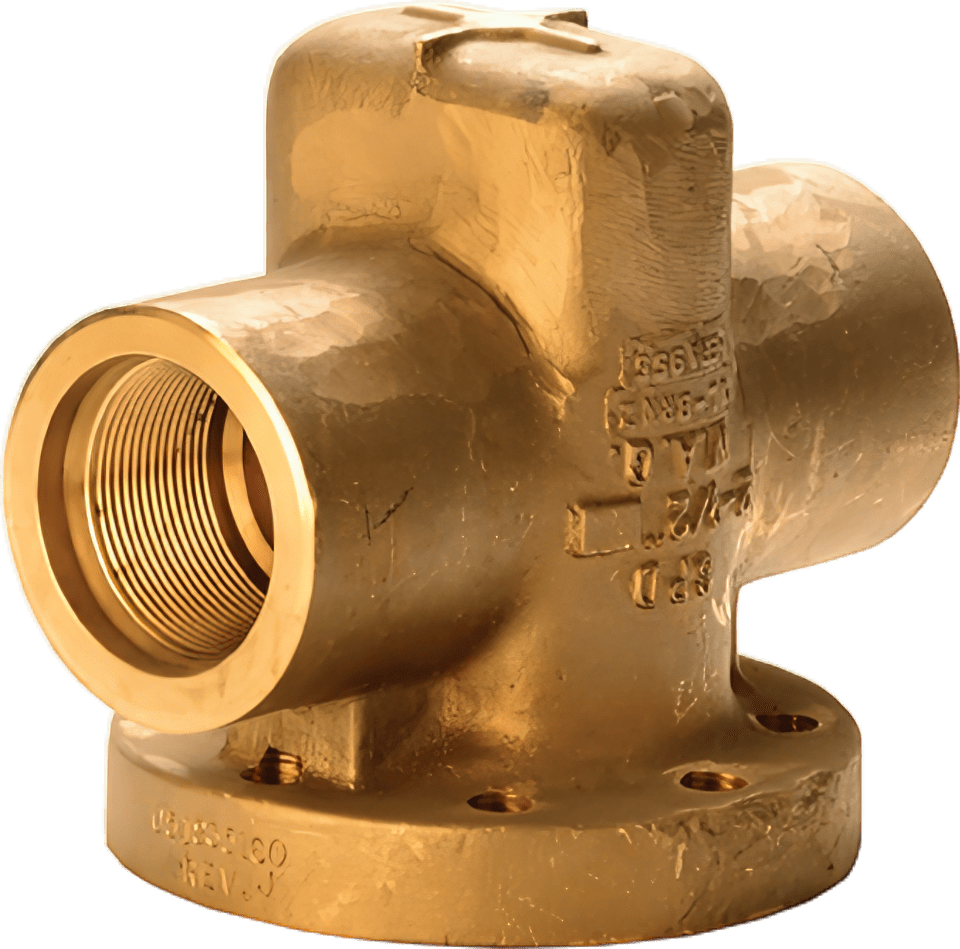

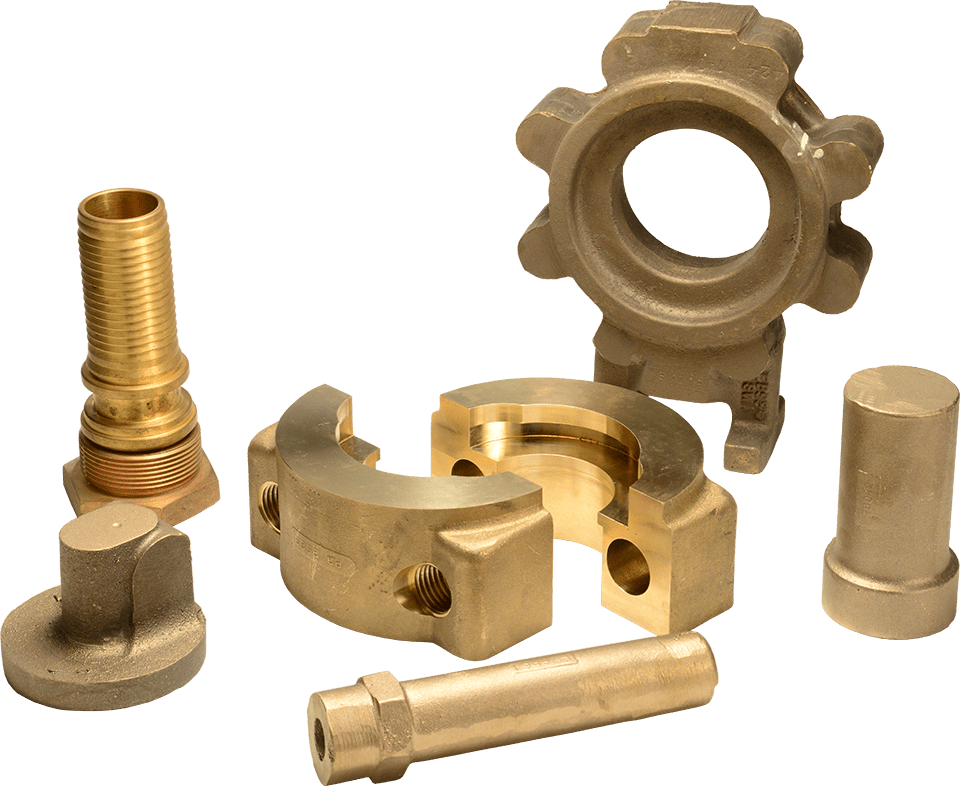

Bronze Castings

The experts at Erie Bronze & Aluminum have over 20 years of specialist experience in non-ferrous bronze green sand casting. EBA bronze alloy castings are crucial components in products the world over. With state-of-the-art molding and melting facilities, including automated molding lines, cope drag molding lines, and six electric furnaces with up to 2000lbs in melting capacity, there is no project too big or small.

At the heart of the foundry is a newly installed high speed DISA MATCH 20/24 automatic mold making machine dedicated to the production of non-leaded bronze and castings up to 100 pounds. The 6 inch to 8 inch variable height cope and drag provides ample depth to produce a wide variety of castings. The highly automated continuous flow process creates a high-speed foundry operation with quick change flexibility to meet the most demanding delivery requirements. From a few parts to hundreds of castings, Erie Bronze can deliver in spec and on time.

We pride ourselves in advising clients on the best suited bronze alloy for their individual needs and specific applications.

Aluminum Castings

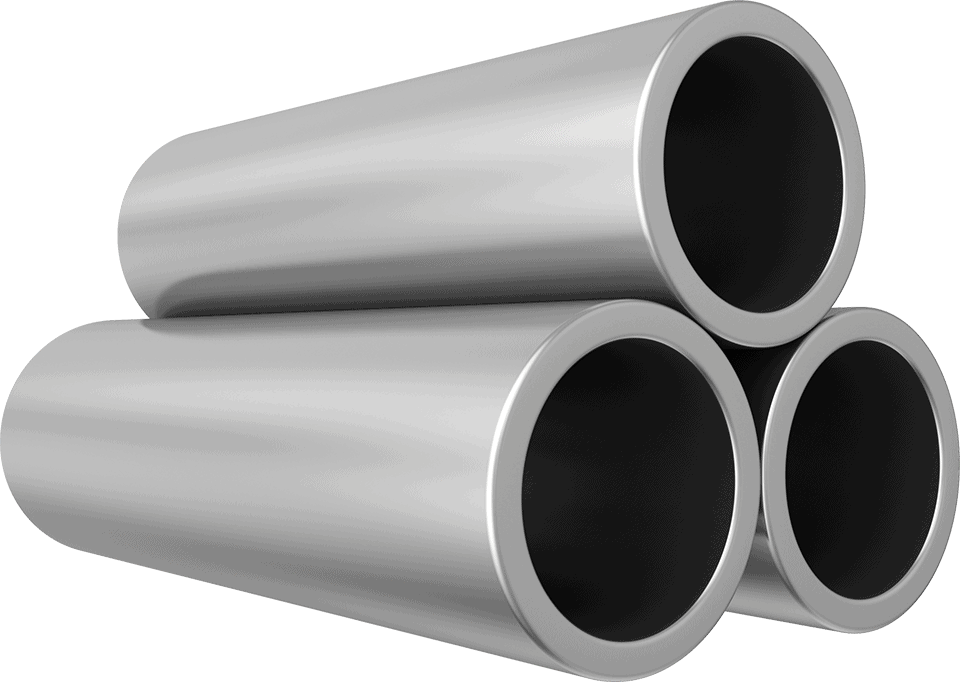

Erie Bronze & Aluminum supplies rough machined aluminum tubes and rings typically used in labyrinth seals, bearings, and bearing housings. We custom make all components to your required dimensions to help cut down on your machining.

Aluminum labyrinth seal and bearing material cast at Erie Bronze offers unparalleled quality both in the elimination of porosity and metallurgical consistency. Cast 850, 852, and 443 aluminum tubes and rings have a maximum 13 inch length and minimum 3.5 inch outside diameter, providing an excellent labyrinth seal and bearing qualities, good compressive yield strengths, and excellent lubricity and machinability as opposed to other materials like plastics and AL6061.

We’ll manufacture your components down to the exact specifications with no minimum quantities. Whether you need 1 or 100 or more pieces, we’ll meet your spec in any size and volume.

Glass Container Molds

Erie Bronze specializes in bronze glass mold components such as neck rings, bottle molds and bottom plates. These components are cast using proprietary Eballoy® non-ferrous alloys designed to improve wear and corrosion resistance, while offering glass-makers thermal conductivity ranging from 18 to 37 (Btu/sq. ft./ft/hr/°ft) at 850°F.

Erie Bronze produces neck rings in an as cast or semi‐machined condition with the mating faces milled, one or more of the outside diameters turned and ends faced (additional features such as face vents can be included), or finish machined. Our in‐house machine shop measures each set for half on half and verifies the fit between the male and female halves (“shake”).

Upon request, Erie Bronze also offers our high quality neck rings with a nickel insert. The insert is available in Rockwell C hardness ranging from 30 to 44.

Value Added Services

EBA offers add-on services for customers such as heat treating, machining, comprehensive logistics, X-Ray (RT), and LPI (PT). We proudly commit to providing customers with the best service, technical expertise, finishing, and delivery by continually evaluating and improving our practices, technology, and equipment.

Meeting the highest standards in customer care and product quality is our first priority.